Success Stories

- Home

- Success Stories

Result of the drive was: A clean, Tidy & Shining Office with basic concept of “A place for everything and everything at its place.”

Areas covered were all offices, IT Room and canteen.

Key objectives were to improve 5S Level beyond 70%, Quality Level by 30% or more, reduce inventories and create safe Work Environment avoiding any accidents.

Over and above, the objective was to make space and accountability for New Parts and creation of SOP’s to track KPI’s.

Basic activities taken up were 5S, 3-Fixed & Visual Control, Introduction of 2-Bin Concept, Flow Production system, FIFO etc., innovation in storage practices, planning & monitoring activities etc

.png)

.png)

As per latest information, inventories have come down to well below Rs. 200 Crores which means over 20% reduction.

Typical results have been an enviably World-class Storage system with superb 5S, 3-Fixed and Visual Control.

.png)

.png)

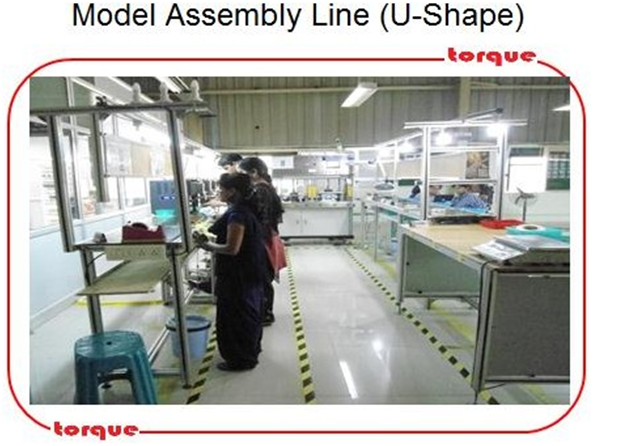

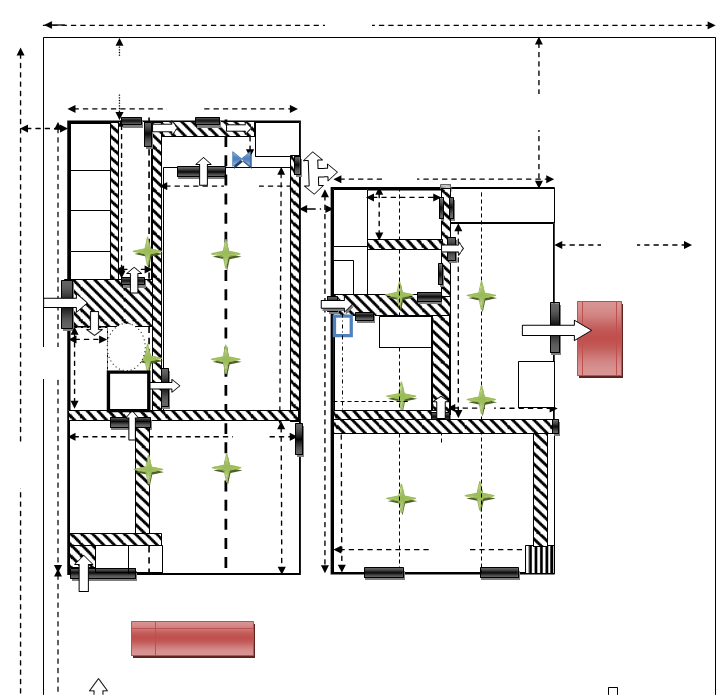

Achievements were implementation of model flow line, excellent 5S & Visual Control, more than 100% increase in productivity, reduction in rejections & reworks by 50%, reduction of WIP inventories from 10 hours to 1-hour, and savings in space by 50%.