Services

- Home

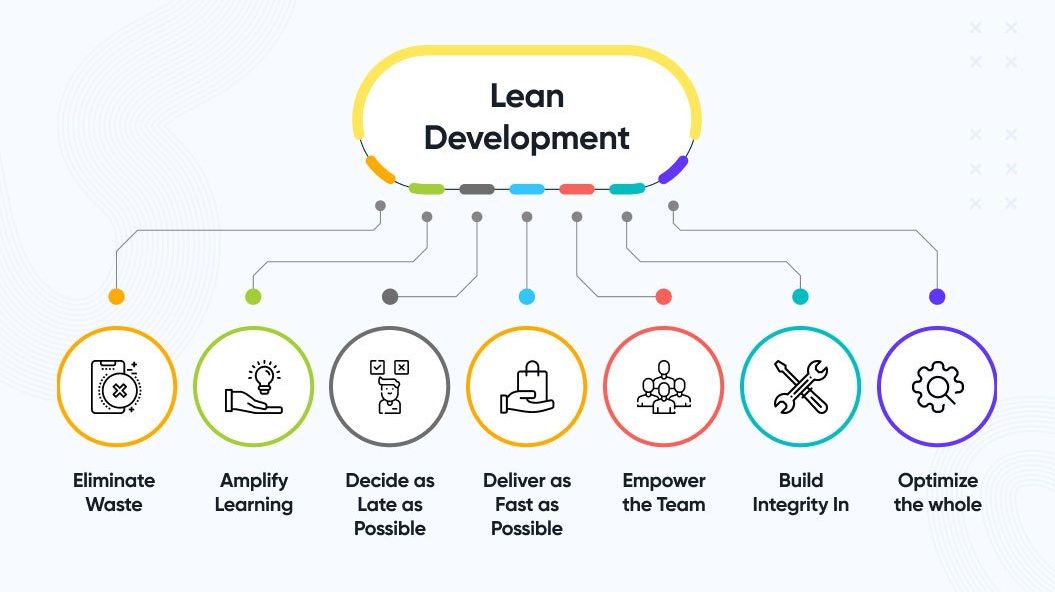

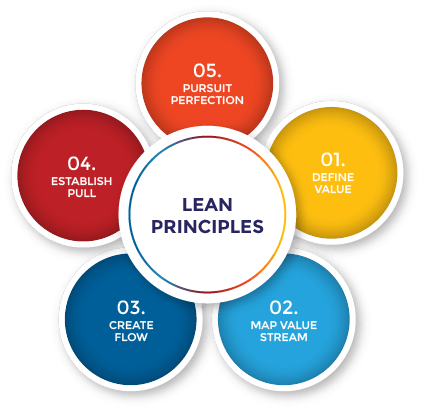

- Consultancy (5S & Lean Reform Projects)

Through our Total Handholding concept (THHC) involving our Consultants and Executives

Our Consultants play a guiding role while our Executives become a part of your in-house team and demonstrate how to do